How Automation can increase your production & make the process operator independent

Economic justification for investing in automated options on a single station thermoforming machine

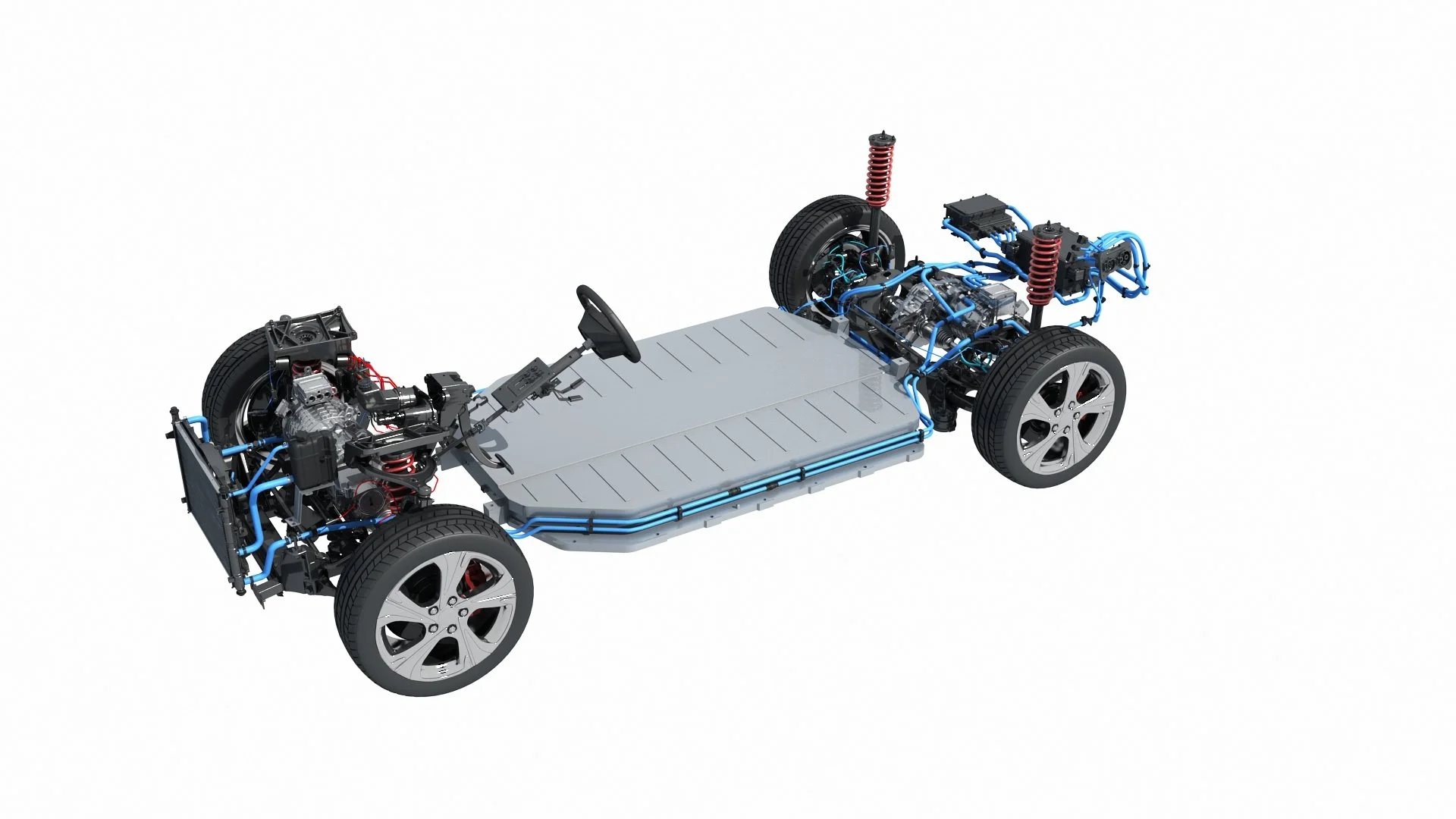

Why electric cars will require thermoforming ++ technologies

The future of EVs is in the design & manufacturing of top hat, learn how thermoforming ++ technologies can help shape the future of EV design

Thermoforming ++ technologies for Making Parts of Agriculture & Off-Highway Equipment

LFI & SRRIM process integrated with thermoforming

How 2-sheet forming can replace Glass Fibre parts in Commercial Vehicles

2-sheet forming is made using ABS/PMMA for aesthetics on A-side & rABS B-side for re-inforcement for strength.

Using Thermoforming to make Jacuzzi Spas & Bath-tubs

Using thermoforming to make spa bathtubs using acrylic

Machinecraft's launches all new all electric PF1 Series

All electric fully automatic thermal vacuum moulding machine

Why Thermoforming?

The reasons to choose thermoforming process for product development using composite material

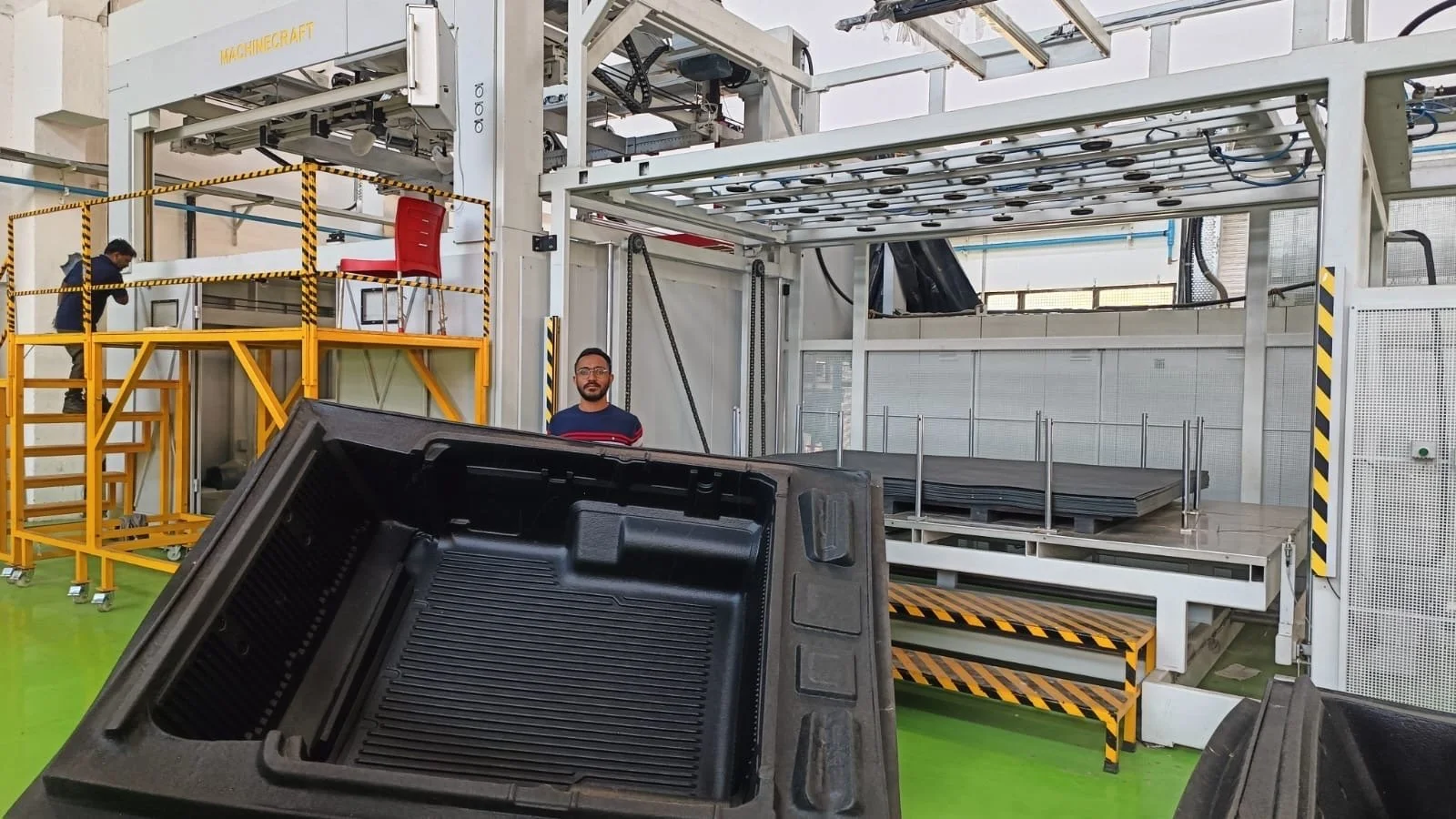

Machinecraft builds India's largest Vacuum Forming Machine

XXL sized thermoforming machines

Using Thermoforming for Making Parts for Electric Vehicles (EV)

Using thermoforming process for making EV parts

How Machinecraft co-developed Medical Liners to store Vaccines - in less than 8 weeks

Read this story to know how Machinecraft can help you develop your next thermoformed part